What’s the difference between dry fog and wet fog system?

What is the dry fog system?

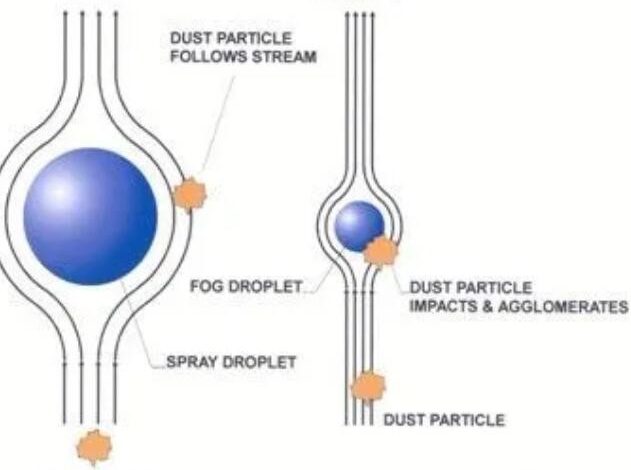

Before understanding dry fog, you first must understand what micron is. A micron is a unit of length. Generally speaking, what we call air pollution PM2.5 refers to particulate matter of 2.5 microns. For comparison, the size of human hair is 60~90 microns, while the water particles produced by dry fog are within 0.1-10 microns in diameter. Using such fine particles to absorb harmful dust particles in the air, such as PM2.5 and PM10, as mentioned before, such equipment is called a dry mist system. It uses modular design technology and consists of the following components:

- Dry misting machine

- Air compressor

- Controller

- Water and gas connection pipeline

- Automatic control system

What is the wet fog system?

The wet mist system is also called a high-pressure misting system, and the mist particles it sprays are usually within 10-30 microns. This equipment does not need compressed air. It pressurizes the tap water with a high-pressure pump and then sprays it through the atomizing nozzle. This system can help you save a lot of costs. However, the flow rate of the atomizing nozzle is low, the area that can cover is limited, the water pressure requirement is huge, and the pump set also needs frequent maintenance. It uses high-pressure plunger pump technology and consists of the following components:

- Misting pump

- Atomizing nozzle

- Nozzle base

- Pipe fittings

- High-pressure pipeline

The different features between the two systems:

- The working path of the dry fog system is water and air, while the wet fog system only needs water.

- The dry fog system produces particles below 10 microns, which is easier to absorb small particle molecules; The wet fog system produces particles above 10 microns, which is easier to absorb larger particles.

- The dry fog system is often used in fine dust removal to protect the workers’ health on-site; The wet fog system can be used for dust removal and humidification and cooling disinfection and landscaping.

- The dry fog system will quickly evaporate in the air; The wet fog system can stay in the air for a while, which will make people feel “Humidity,” but neither will wet the ground.

- The dry fog system needs to use professional two-fluid nozzles. The number of nozzle layouts is small, but the cost is higher; The wet fog system uses available high-pressure nozzles, the nozzle layout is dense, and the number is large, but the price is lower.

- The dry fog system is more commonly used in industrial fields that require dust reduction; The wet fog system can be applied in industrial fields and other industries such as humidification, cooling, disinfection, and landscaping, with a broader range.

- The dry fog system generally uses stainless steel material, which is not easy to be corroded, has a long use time, and has a long maintenance cycle; The wet fog system can both use stainless steel or brass material, according to your different needs, and the cost is lower. It can also be purchased and used at home.

The different applications between the two systems:

The dry fog systems can be used in the following industries:

- Steel plant

- Thermal power plant

- Fuel plant

- Coal handling plant

- Conveyor belt

- Sand and gravel plant

The wet fog system can be used in the following industries:

- Warehouse

- Paper mills, timber mills

- Hen farm, horse farm, pig farm, cattle farm

- Cellars and wineries

- Tobacco factory

- Air conditioning system

- Quarry, mine site

- Ship loading and unloading areas

- Waste treatment plant

- Landscape design

Check out our amazing blog.