Gas Turbine – All About Its Working Principle

Did you know that gas turbine technology is used in most power plants? However, when you look at history, it becomes apparent that this technology’s experimental stage was already established by the 1900s.

The first gas turbine control system electrical power system was created in 1939. However, its primary purpose was to power airplanes. As a result, the gas turbine’s economic benefits and dependability are unmatched.

What is the gas turbine concept behind this enormous machine, utilized in aviation, industry, and other applications?

The following discussion intends to provide a basic understanding of the devices

- components

- operation

- power increase

This is majorly for individuals who are unfamiliar with this technology.

Suppose you’re thinking about buying a gas turbine or want to learn more about the ones you already have. This blog post will equip you for a more honest conversation with the vendor or manufacturer. Furthermore, with this, you will understand the fundamentals of gas turbine physics.

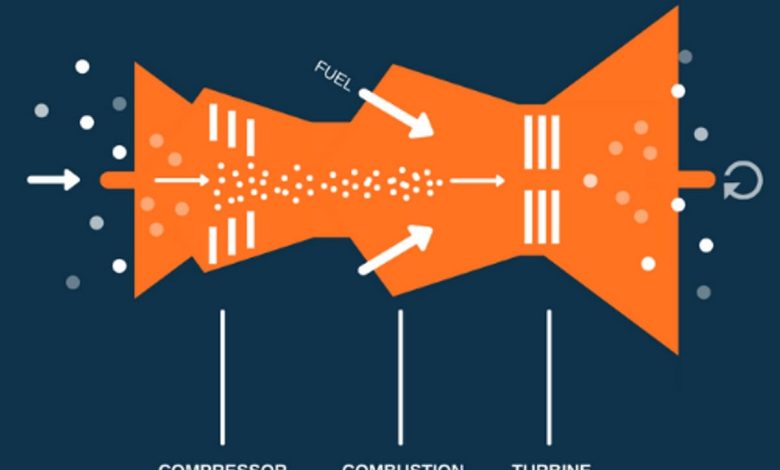

The turbine comprises three components: a compressor, a turbine, and a combustion chamber. The pressure of the combustion air increase by the compressor. This extracts energy from the gases and then burns the fuel/air mixture in the combustion chamber.

The Gas Turbine Control System theory consists of several categories, some of which you are undoubtedly familiar with:

- Heavy-duty turbines

- Industrial-type gas turbines

- Small gas turbines

- Micro gas turbines

- Aero derivative gas turbines

What the Turbine Is and How It Works

The equipment’s task is mainly to convert fuels, such as natural gas. It is majorly convert into mechanical energy according to the gas turbine theory.

This power drives a generator that generates electrical energy. Next, the ambient air enters the compressor as a precursor to everything else. The compressor usually increases the temperature and pressure of the air, which it then directs to the combustion chamber.

In this section, the air-fuel mixture is heated at high pressures and temperatures (over 2000° F) to create a scorching gas that goes through the turbine blades, accelerating them to an incredible speed.

In other words, it helps work, making the drive shaft spin rapidly. This procedure generates power that supplies to the grid. An open Brayton Thermodynamic Cycle is what this refers to.

Turbine Power Theory: different strategies to boosting an existing application

Turbine efficiency may affect due to the various things, including waste heat. Recuperation is a technology that recovers energy from the exhaust. Aside from that, one of the most significant turbine power advancements has been in overcoming temperature restrictions on ambient intake air temperatures.

Operating a gas turbine in ideal (ISO) conditions require a relative humidity of 60% and a temperature of 15° C. If the ambient temperature is more significant than the ISO temperature, the operation may reduce. This is a typical difficulty in hot regions. Where the ambient temperature regularly exceeds 30° C.

Moreover, this results in a reduction in turbine output and altered exhaust gas properties.

Gas Turbine power capability

Turbine power capability also has improved thanks to the advent of technologies like these. It is also leading to improvements in more robust turbine materials. Is it possible that you’re asking how long it takes to implement such a system?

The Turbine Inlet Air Cooling Technology’s fast turn-around time. They are making it ideal for demanding surge power demands. Designing and maintaining a gas turbine’s inlet air cooling system is a complex procedure.

This is due, especially to the fact that external conditions must be considered alongside traditional gas turbine principles. Furthermore, several factors impact the procedure:

- air temperature after cooling

- chilled water temperature

- condensation technique

Hence these are just a few examples.

Increase in Power: How to Do It

The primary focus has been on turbine life, leaving performance unaddressed for years. Performance of gas turbine is now possible. It helps introduce and adopt turbine inlet air cooling technologies.

The objective of cooling systems is to boost the amount of combustion air flowing through the compressor.

As a result, density must increase to enhance mass flow rate. This improves both the power output and fuel efficiency of the turbine. What more could you ask for as a power plant owner or manager?

Summary

For many power plants, natural gas is still the most common fuel. This indicates that gas turbines will not be going away any time soon. So, there is much to learn about gas turbines as a fascinating machines. The information we provided here will for sure assist you in entering the market with greater confidence.