Know your gas turbine control system a little better

A gas turbine is a machine that converts natural gas or other fuels into electrical energy. Aeronautical companies primarily use them to power airplanes and different types of aerial machinery like Jet planes.

A gas turbine control system is the heart of turbines as it controls the routine operations of a turbine and ensures the smooth running of its processes.

Functioning of a Gas turbine control system

The gas turbine control system is a critical component of a gas turbine. It requires a highly qualified and technical stall to run a turbine smoothly. What’s more important is having a control system that can keep all the operations in check. The primary function of a gas turbine control system is to ensure the correct fuel, air, and emissions control is in a statement.

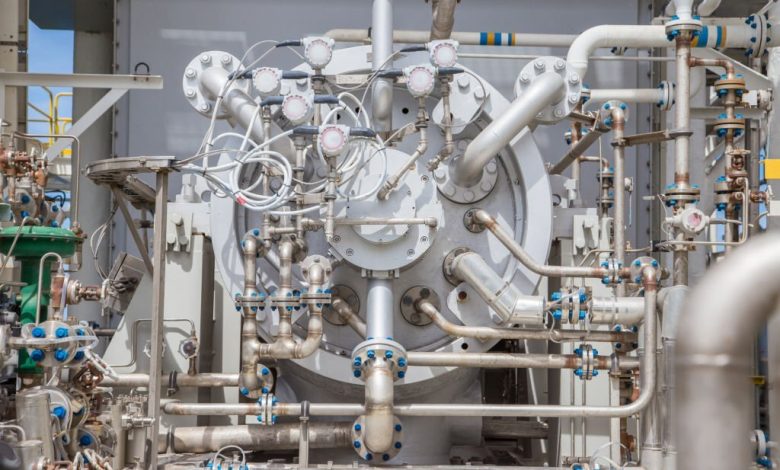

Moreover, a gas turbine system shields the turbine from wear and tear by maintaining the stability of the routine operations. The system controls the unit’s temperature, flow, the pressure of the gas, and auto-positioning in the best direction.

Apart from these salient features, some other practical applications of the control system include:

Startup protocol

A gas turbine must be able to start up automatically. It is only possible with the help of a gas turbine control system. This system speeds up the unit on its own accord and allows the perfect synchronization with the grid remotely. Furthermore, it helps achieve the desired settings by gradually increasing the load of operation.

Safeguarding the routine unit procedures

A gas turbine control system can also be termed an autopilot for a gas turbine. It helps keep the systems in check and warns the operator if something gets off track. For instance, if the turbine is overheating or the rotors are over speeding, the operator is instantly notified through a digital screen or alarm system. Additionally, a control system ensures no flame loss, lubrication, or unknown vibratory motions in the turbine.

Role of Thermocouples

Every control system is equipped with a pair of thermocouples. These thermocouples allow regular inspect the thermal rise and fall of the system. They are mostly mounted near the turbine’s exhausts or the combustions cans.

Speed up keeping

A gas turbine control system computes the turbine’s speed and collates it with the needed momentum. If in case, there is a difference in the required speed and the actual speed, the system will balance out the difference and adjust the fuel valve’s opening to negate the error.

Markets’ division for Turbine control system

Although various companies produce turbine control systems. They mainly make systems based on their area of expertise. However, four factors come into play before deciding which system will work best per your needs.

By type of turbine

It is crucial to ensure the type of turbine the turbine control system is most compatible with. For example, it can work better on steam or water turbines than gas turbines.

For ease of installation

The control system has a separate market for turbines depending on their ease of installation and where the installation will take place on the turbine system.

By use of turbine

Companies use turbines in various equipment and machinery. It can either be in Marine or Naval forces or at an oil refinery. Or the turbine might be use in aeronautical machines like an airplane. A control system heavily depends on where its application is.

By Topography

A turbines’ efficiency also relies on which location it’s used. For instance, if a turbine is used in a hot locality or a tropical region, you will need better thermal checking and more efficient overheating control.

At Direct Turbine Controls

Direct Turbine Controls collaborates with the world’s largest oil and gas, power, and energy-generation industries to provide dependable, certified services and lab-tested gas turbine replacement parts for the brands you trust.